TRIDENTPONTOONS

Construction

Construction

| HOME |

|---|

| Model |

| Propulsion |

| Model & Equipment |

| Trailers |

| Custom Exotics |

| Construction |

| Enviromental |

| Shipping |

| Customer support |

| PreOwned Vessel |

| Trident World |

| FAQ |

| MAP |

12

IMPORTANT REASONS TO CHOOSE TRIDENT

Trident places full emphasis on structural design. We put the workmanship and money where it counts ... in the basic design structure. We incorporate only the highest grades of marine aluminum, stainless steel, and wood products available. Our continuing and exclusive dedication to quality and technique of construction result in a product built for years of demanding service.

We

know from experience...and have the safety record to prove it!

We

realize that our customers cannot examine each and every one of the

features incorporated in the construction of our superior quality vessels.

There are 12 exclusive features incorporated in every Trident pontoon

vessel. We have prepared the following list with photographs to help you

understand and visualize why Trident boats really are the finest available

in design, construction, and quality on the market today!

1.

Pontoon material.... Trident pontoons are constructed from the

highest grade of .125 and .190

H-5052 alloy corrosion-resistant Marine grade Aluminum.

2.

Keels.... Our heavy-duty keels are solid .250 aluminum; welded

full length to provide added strength and protection to each pontoon hull.

3. Bulkheads.... Every 5-foot pontoon section is manufactured with a solid airtight bulkhead. This assures compartmental buoyancy, added strength, and maximum safety.... These boats are virtually unsinkable!

4.

Inspection ports.... Each 5-foot airtight section of the

pontoon is provided with a 3-inch inspection port. Each of these ports is

sealed with a removable expansion cap and through hull inspection plate.

5.

Pressure test plugs.... Along with inspection ports, each

5-foot section includes the required U.S. Coast Guard air pressure test

points.

6. Nose cones and End caps.... The nose cones and end caps are extremely important! Because the forward and aft areas of the vessel are the areas most likely to be damaged, all nose cones and end caps are built with airtight chambers on Trident boats.

7. The “M” Bracket.... These brackets are designed to connect the pontoons to the deck. They are designed to maximize the freeboard and insure a dry, safe ride. The “M” brackets are each 36” long, .125 Marine grade aluminum and welded full length to the pontoon.

8. Cross Members.... Trident uses .250 thickness, 2”x 4” cross members that are designed specifically for structural use. These are bolted together to join the “M” bracket to the deck. Transom and support members are .190 and .250 in thickness. Incorporating this “structurally designed” type of cross member absolutely guarantees the structural integrity of Trident pontoons!

9. Deck Structure.... All of our decks are built with 3/4 inch, 7 ply Douglas Fir. Greenwood Forest Products supply this .40 CCA Pressure Treated plywood. Greenwood is the absolute leader in producing material for boat decking and supplies to us a 50-year guarantee with their XL-50 plywood! Trident recognizes that structural integrity combined with low noise acoustical values result in a deck structure of superior quality and longevity.

10.

Hardware.... All fastening hardware including bolts, nuts,

washers, and associated deck hardware are of the highest marine grade

aluminum and stainless steel to assure quality and longevity in our

Trident vessels!

11.

Transom Mount.... T P P * Again, Trident has developed another

unique feature. A computer designed high performance motor mount. This new

design is constructed solely of 3/16” welded aluminum, and is self

bailing.... This is just another example of our commitment to continue

product improvement and another accomplishment in the category of design

excellence! *(patent

pending)

*(patent

pending)

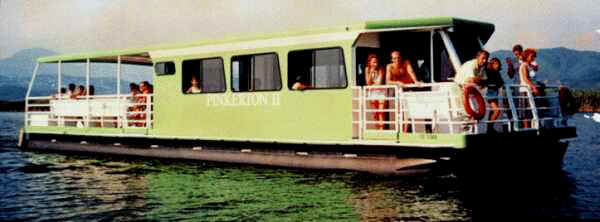

Water Taxis

Tour Boats

Diner Boats

Glass Bottom

Barges

Dive Boats

Florida Trading Company L.L.C.

PHONE: 352-253 1400

FAX:

352-253 1402

EMAIL: INFO@TRIDENTPONTOONS.COM

13320 SOUTHRIDGE INDUSTRIAL PARK DRIVE, TAVARES, FLORIDA 32778